The idea behind the circular economy

The satisfaction of even basic human needs such as housing, nutrition and mobility require the use of natural resources. In the current economic system, the needed resources are obtained and delivered via processes of extraction, processing and trading for further manufacturing. In a linear economic system, once used, materials and products lose their functionality and become waste, which is often burned or landfilled. This global system of provisioning and discarding causes an increasing geographical separation between production and consumption, resulting in a web of supply chains that is highly complex, materially and energetically intensive, and environmentally harmful.

The circular economy abandons the linear economic concept of “take, make, dispose” by feeding resources back into the economy, which would have otherwise been considered as exhausted, or as having lost their former purpose. By reducing the need for virgin resources and focusing on local economic activities, a circular economy promises economic and social prosperity whilst limiting impacts spanning from social inequality to depletion of natural resources and environmental pollution. A study by Circle Economy (2021) strengthened the plausibility of this objective estimating that a shift to a circular economy has the potential to reduce global natural resource use by up to 28%, GHG emissions by up to 39%, while still improving economic growth.

The Building Blocks of the circular economy

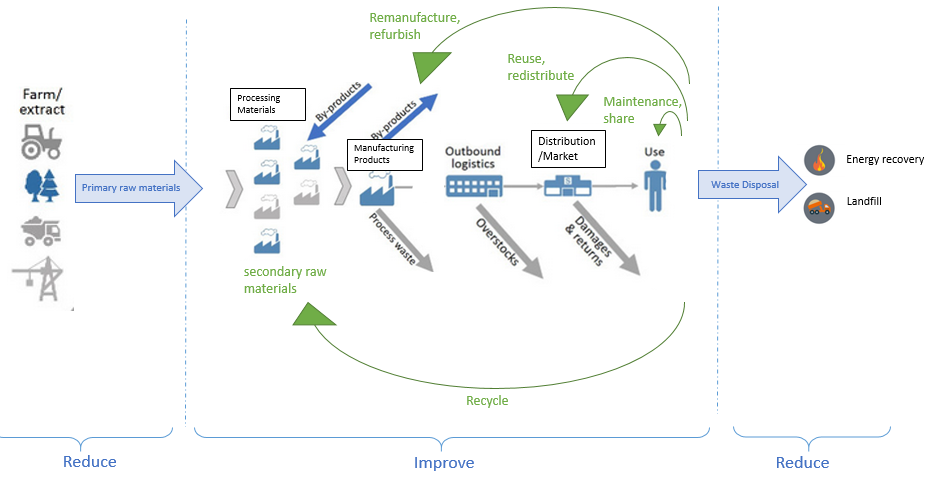

The circular economy pursues a sustainable development and harmonious intergrowth of both the economic and the social system, in concomitantly preserving a healthy natural environment. By improving the productivity of materials and products (see graph below), both the extraction of virgin resources and waste generation can be reduced.

Increased material productivity can be achieved by inter-looping the life cycles of materials, and these loops then to be run through as many times as possible. A tight circle of product sharing and reusing, for example, does not need the input of new materials, and requires less energy than when processing and recycling is needed, such as in the bigger economic product loops.

Economic and material loops can be achieved by (a) designing circular products, created expressly for circular use and re-use, and by (b) establishing circular business and purchasing models.

Intentional product design can help extend product life-spans and close material loops, as new design strategies ensure durability, maintenance, repairability, upgradability, compatibility, and ease of deconstruction and recycling.

Circular business models focus on sharing, maintenance, redistribution, and manufacturing. Sharing allows for increased use rates of products by providing access instead of ownership. Maintenance focuses on service performance, which becomes the responsibility of the service provider in exchange for retaining product ownership. Redistribution means re-sell and buy-back business activities of products having reached the end of their usage. Finally, (Re)manufacturing focuses on refurbishment and maintenance of used parts and components to allow resale for incorporation into existing products.

New consumer-end purchasing models are also an important part of the circular economy. They include access- or use-based purchasing models, under which products are purchased for a certain amount or type of use, or for an access period (i.e., leasing) – for instance, cars, bicycles, clothing, or power tools. In comparison, performance-based models describe the purchase of a defined performance or service that is not bound to a particular product or good, opening up service delivery to efficiency considerations. For example, a company can buy the service of the lightning of an office building, instead of the illuminants. Finally, result-based models focus on a defined service result (e.g., pay-per-performance).

These building blocks show that a transition to the Circular Economy requires strategic participation of both producers and consumers, and that it must occur in combination with technological innovation. In this manner, linear use of materials and products can be abandoned by looping supply and use chains back into the economic system.

Circularity Today

In 2023, almost 100 Gt of raw materials such as minerals, biomass, and fossil fuels were extracted worldwide. Only about 7% of the materials extracted were recycled (7 Gt) and re-entered the economic system (Circle Economy, 2023). This relationship underlines the considerable potential that circularity holds, and its possible impact in shifting away from raw material extraction towards reuse and recycling of materials.

Economic and material looping opportunities do not solely depend on product design and business models, they also are subject to the type of materials being processed. Biomass, for example, is largely used up in the form of food, feed, and fuel, and is therefore difficult to reuse. Fossil fuels have a low circularity potential for the same reason. Instead, metals and minerals have an almost infinite reuse and recycle potential.

For instance, estimates show that the global end-of-life aluminum recycling rate is 55%, corresponding to new aluminum having a recycled content of 35% (OECD, 2019).

The Circular Economy in the European Union

The Circular Economy is a more comprehensive concept than traditional recycling, and to assist and achieve the systemic economic transformation the European Commission launched the Circular Economy Action Plan in 2015. In this concrete and ambitious programme of action, a set of indicators was established to monitor progress in all dimensions of the circular economy, including competitiveness and innovation, production and consumption, waste management, and secondary raw material use.

A revised and extended Circular Economy Action Plan was published in 2020 with a stronger emphasis on sustainable product life cycles related supply chains, and initiatives for transparency (European Commission, 2020).

A new set of indicators was also introduced, reflecting a shifting in focus towards a more holistic view of consumption and associated impacts. It includes footprint indicators, such as the material footprint and draws attention to resilience and self-sufficiency, for example, by including material import dependency. Specific indicators were also introduced to measure performance for public procurement, innovation, competitiveness, and trade of recyclable inputs, which complement the monitoring framework (European Commission, 2023).

From the Action Plan, a key framework indicator is the “circular material use rate” (CMUR), which provides insights into the circularity of a country’s economy. The CMUR measures the share of material recovered and fed back into the economy providing evidence of prevented extraction of primary raw materials.

In 2021, among the EU-27, the Netherlands had by far the highest CMUR (33.8%), followed by Belgium (20.5%) and France (19.8%). The lowest CMUR were for Romania (1.4%), Ireland (2.0%), and Finland (2.0%).

Many EU member states increased their CMUR in the period between 2011 and 2021, displaying an upward trend in economic circularity. The Netherlands showed the largest absolute increase (+8.8 % points), followed by Malta (+6.9% points). But in the same period, a number of countries also decreased their CMUR. Such as Luxembourg (-16.9% points) and Finland (-12% points).

In absolute terms, some of the big economies of the EU also show the largest amounts of circular material recovered and fed back into the economy. In the case of France and Germany, these quantities amount to 155 and 150 million tonnes, respectively.