The importance of Circular Economy actions for GHG emission reductions

Climate change mitigation is one of the overarching challenges of our time. Most actions currently taken to tackle climate change are related to energy use. This is highly important but does not (directly) address GHG emissions that are related to material use, which contribute 45% to overall global emissions (Ellen McArthur Foundation, 2019). If only direct emissions of material production are considered, these account for 23% of global GHG emissions (Hertwich, 2019). The remaining share are indirect emissions, stemming from the energy required for material production and processing, which will also decrease in case of lower material consumption. The opportunity of tackling almost half the global emissions needs to be seized, considering the enormous challenge to reach the 1.5°C target. Hence, tackling emissions related to material use is not a marginal issue but constitutes a significant step towards the decarbonization of the global economy.

Reductions of material use so far have not been at the core of sustainability measures. This fact underestimates the consequences of material use for the environment, including associated emissions. However, it has been shown that resource efficiency measures combined with ambitious policies to cut emissions related to energy use and agriculture can generate notable additional benefits for reductions of GHG emissions, while creating higher potentials for economic growth (Hatfield-Dodds et al. 2017). Before this background, establishing a Circular Economy (CE) becomes even more important, as this concept aims at increasing material efficiency and reducing the demand for primary materials (for more information on CE, see our specific story “Circular Economy: a smart way of using materials”). This is particularly relevant given the fact that current global material use of around 95 billion tonnes (Bt) is expected to increase to up to 180 Bt by 2050 (UNEP, 2016), with a corresponding increase in GHG emissions.

Emissions that are directly or indirectly linked to material use can be addressed very effectively by two overarching strategies. The first addresses technological innovations, such as more efficient and less wasteful processes, for instance in the construction and transport sectors. The second is the transition to a more circular economy. This story focuses on the latter, and especially on those fields of action that are characterised by high emission intensities and at the same time high potentials for reductions through CE measures.

Hot-spot materials, sectors and industries with the highest GHG emissions

Only four specific materials and related processing activities are responsible for around 70% of emissions from material production. These are iron and steel, aluminium, cement, and plastics (IRP, 2020). A large share of the emissions linked to these materials are caused by only two important segments of the construction and automotive industry, which are buildings and passenger cars. For instance, in the EU, these two segments are responsible for 50% of emissions related to the use and processing of the above-mentioned materials (Material Economics, 2018). Thus, addressing material use in these two sectors can lead to high emission cuts.

All four major material categories, i.e. biomass, fossil fuels, metal ores and non-metallic minerals, are used mainly in the secondary sector. As an example, the figure below depicts the consumption of non-metallic minerals in the world region ‘Asia and Pacific’. The dominance – especially in this material category – of the secondary sector and particularly of the subsector construction can clearly be seen. Therefore, policies that aim at lowering resource consumption are most effective when addressing production processes (e.g. by enabling and incentivising the use of more secondary raw material inputs) or making parts of new production obsolete through facilitating a change in consumption patterns (e.g. sharing economy or longer product lifetimes).

Note: Figure based upon the 2019 version of the IRP MFA database. Will be updated soon. Hover over the graph to view the respective values. For a further analysis of the most relevant sectors in countries world-wide, see the online tool SCP-HAT.

Circular Economy measures that reduce GHG emissions

The largest emission reduction potential through CE measures regarding certain materials and sectors coincide with the highest emission intensities described above. The only exemption is the potential related to plastics and rubber products, which is less significant.

Foremost, the iron and steel production offers huge reduction potentials and already today, one third of global steel demand is met by recycled steel. This share can be increased considerably, for example, through the establishment of markets for steel scrap and the reduction of losses, i.e. more effective collection of scrap and more efficient processing. Additionally, current practices of down-cycling from high-quality steel to e.g. construction steel could be reduced through more sophisticated sorting and processing of end-of-life steel throughout supply chains. An important aspect is contamination with copper, which could be handled by more careful dismantling of cars, for instance.

Also aluminium and cement offer good opportunities for reusing and recycling. For the former, reducing losses and avoiding down-cycling are also the most important aspects. For the latter, making end-of-life concrete more easily accessible through smarter design and dismantling processes is a key challenge.

In general, a possible cross-cutting measure to promote and incentivise circular economy efforts and a more efficient use of materials is unveiling their true costs and pricing in externalities. This can be done by the introduction of taxes on the extraction of virgin materials and the abolishment of direct and indirect virgin material subsidies, such as tax exceptions, lenient approval procedures or direct support of production (IRP, 2020).

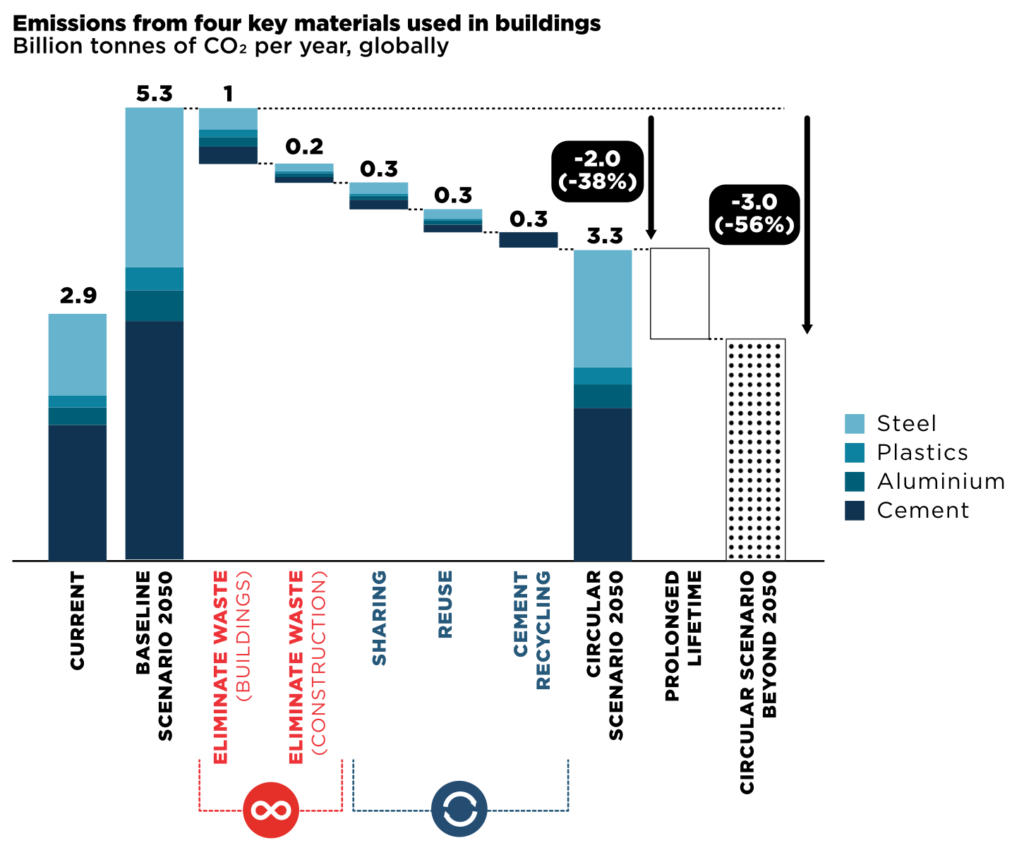

Also the above-mentioned hot-spot segments – buildings and mobility with cars have considerable GHG emission saving-potentials in the context of a circular economy. As for buildings, a set of measures could lead to a reduction of projected emissions of the sector by 56% in 2050 (see figure below). One of them is turning away from wasteful building design. In many cases, it is possible to reduce the input of cement and steel, without impairing the stability. In addition, more efficient construction technologies such as the usage of prefabricated elements or 3D printing will further reduce waste. For buildings that are already in service it will be key to increase the intensity of use, enable and incentivise urban mining, i.e. reusing or recycling materials from existing structures. Finally, prolonging the lifetime of buildings through foresightful policies, favouring renovation/refurbishment over new construction, and improving durability of newly constructed buildings can contribute greatly to emission savings (Ellen McArthur Foundation, 2019; Hertwich et al., 2019).

(Ellen McArthur Foundation, 2019. Completing the Picture. How the Circular Economy Tackles Climate Change.)

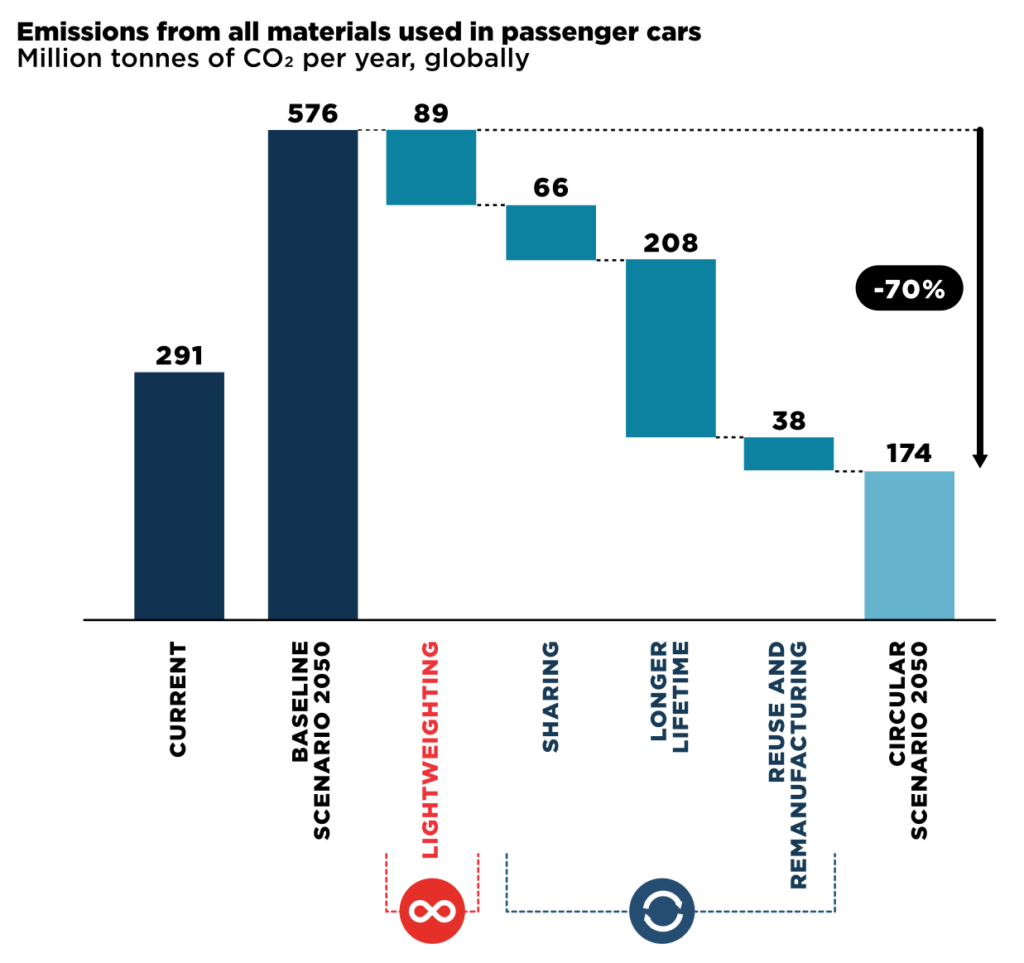

Projected emissions related to the production of passenger cars could be reduced by up to 70% (see figure below). One key measure is to reduce the weight of vehicles through smart design and choice of materials. In addition, reversing the recent years’ trend of increasing size and weight of vehicles is highly relevant. Moreover, a shift from single-ownership to sharing models could also lower emissions considerably. Currently, the overly large car fleet requires large quantities of materials for their construction, and being parked most of the time appropriates a large share of public space. If there is economic proximity between the operators of car sharing businesses and the producers of used vehicles, sharing models also incentivise a higher durability and simpler repair and by that means help increase the lifetime of vehicles. After the use phase, reuse and remanufacturing of vehicle parts could save additional emissions (Ellen McArthur Foundation, 2019; Hertwich et al., 2019).

Nevertheless, despite potential reductions of emissions in motorised individual transport, a shift to public transport and non-motorised options bears even more reduction potential.

(Ellen McArthur Foundation, 2019. Completing the Picture. How the Circular Economy Tackles Climate Change.)

A key take away is that a prolonged lifetime of products entails (at least in the two industry segments described) the biggest reduction potentials of GHG emissions through CE measures. In general, this can be achieved by mandatory requirements for product design, a shift from owning to renting models and promoting repair options.

Potential measures for the implementation on the macro level could be, for instance, additional efforts in the context of initiatives such as the EU Ecodesign Directive (a review of this directive and related legislative documents is envisioned in the New Circular Economy Action Plan of the EU), and the revision of regulations and tax systems. On the micro level, ideas such as repair vouchers, that support local and small businesses and increase the lifetime of products, could be considered.

Given the upward trend for global resource use, it will be crucial to consider measures that reduce overall material use and lead to a more circular economy as key parts of a comprehensive climate policy package. However, it must be kept in mind that circular economy approaches can only be a part of the solution, as the potential of a circular economy to reduce overall resource use is not limitless. Consequently, reducing the consumption of materials by not using them in the first place is another obvious but often overlooked opportunity to cut emissions related to material use.

References

Ellen McArthur Foundation, 2019. Completing the Picture. How the Circular Economy Tackles Climate Change.

Hatfield-Dodds, S., Schandl, H., Newth, D., Obersteiner, M., Cai, Y., Baynes, T., West, J., Havlik, P., 2017. Assessing global resource use and greenhouse emissions to 2050, with ambitious resource efficiency and climate mitigation policies. J. Clean. Prod. 144, 403–414. https://doi.org/10.1016/j.jclepro.2016.12.170

Hertwich, E., 2019. Increased carbon footprint of materials production driven by rise in investments [WWW Document]. doi:10.1038/s41561-021-00690-8

Hertwich, E.G., Ali, S., Ciacci, L., Fishman, T., Heeren, N., Masanet, E., Asghari, F.N., Olivetti, E., Pauliuk, S., Tu, Q., Wolfram, P., 2019. Material efficiency strategies to reducing greenhouse gas emissions associated with buildings, vehicles, and electronics—a review. Environ. Res. Lett. 14, 043004. https://doi.org/10.1088/1748-9326/ab0fe3

IRP, 2020. Resource Efficiency and Climate Change: Material Efficiency Strategies for a Low-Carbon Future. Hertwich, E., Lifset, R., Pauliuk, S., Heeren, N. A report of the International Resource Panel. United Nations Environment Programme, Nairobi, Kenya.

Material Economics, 2018. The Circular Economy – A Powerful Force for Climate Mitigation. Transformative innovation and low-carbon industry. Stockholm, Sweden. URL https://materialeconomics.com/publications/the-circular-economy-a-powerful-force-for-climate-mitigation-1

UNEP, 2016. Global Material Flows and Resource Productivity. An Assessment Study of the UNEP International Resource Panel. H. Schandl, M. Fischer-Kowalski, J. West, S. Giljum, M. Dittrich, N. Eisenmenger, A. Geschke, M. Lieber, H. P. Wieland, A. Schaffartzik, F. Krausmann, S. Gierlinger, K. Hosking, M. Lenzen, H. Tanikawa, A. Miatto, and T. Fishman. Paris, United Nations Environment Programme.